For mini plant and microreaction technology

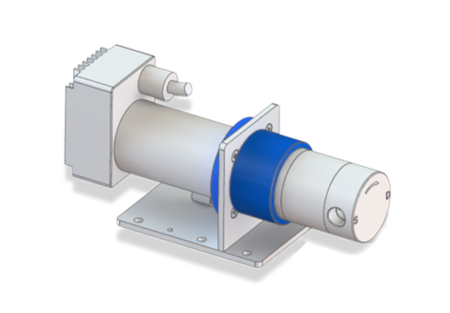

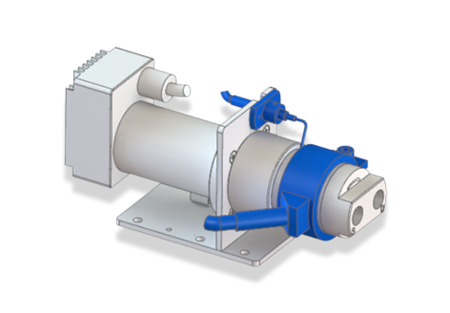

The mzr-6355 micro annular gear pump of the hermetic and chemically inert series is, considering its almost universal suitability for aggressive and corrosive liquids, a revolution in the pump technology. Its rotors and functional elements being made of ceramics, the pump shows the highest chemical resistance and an outstanding resistance to wear. Thanks to the use of SSiC (pressureless sintered silicon carbide) as bearing and shaft material, a magnetic coupling, and case components made out of alloy C22 (DIN 2.4602), this pump will take up any challenge in the chemical industry applications.

Advantages

- High resistance to corrosion

oxidizing and reducing liquids, acids and bases - Long service life

wear-resistant ceramic components - Hermetically sealed

magnetic coupling (NdFeB) - Compact, chemically inert pump head

146 mm long, alloy C22, SSiC, Al2O3 and ZrO2-ceramics - Precision motor and user-friendly control

dynamic DC-servomotor with encoder and microcontroller, - RS-232 or CAN-Bus, analog, I/O

- Precise dosage, low pulsation

rotary micro annular gear technology, no valves

Applications

- Mini plant technology

- Microreaction technology

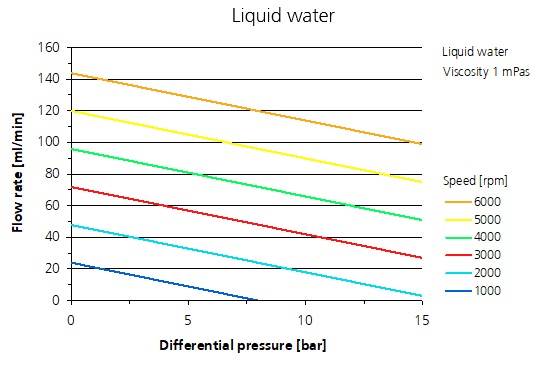

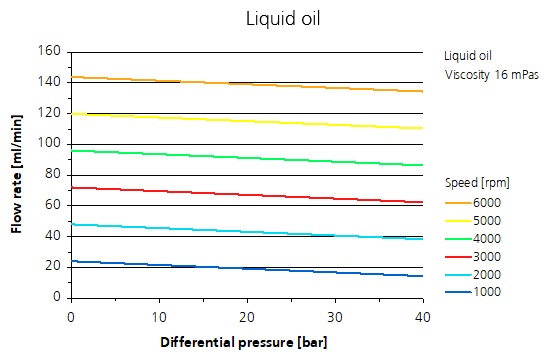

Flow charts

Technical data

Show moreDownloads

-

-

Software

-

-