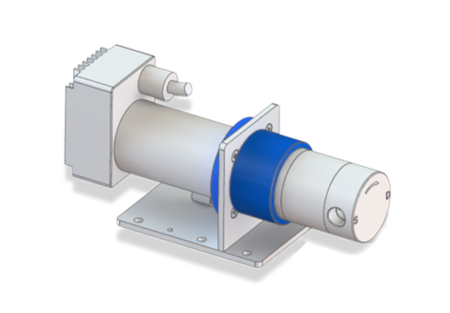

Ex-pump for application in chemical and process technology

The micro annular gear pump mzr-7259X2 Ex of the hermetic inert pump series in its explosion proof version is used for highly precise, low pulsation small volume dosage even of aggressive and corrosive liquids. The compact design combined with high achievable pressures are unique features. The pumps are applied in the field of chemical and process technology. Thanks to the use of rotors and functional elements being made of ceramics, a magnetic coupling, and case components made out of alloy C22, this pump will take up any challenge in the chemical industry applications.

Advantages

- Ex-certification ATEX

conform with EU Directive 2014/34/EU - Precision motor and sophisticated control

ATEX DC-servomotor with integrated microcontroller - Compact, chemically inert

length 354 mm, alloy C22, SSiC, Al2O3 and ZrO2 ceramics - Hermetically sealed

magnetic coupling (NdFeB) - High dosage precision

precision CV < 1 % at low volumes - Low pulsation delivery, low shear stress

rotary micro annular gear technology, no valves

Technical data

-

Flow rate

0.048 - 192 ml/min -

Smallest dosage volume

30 µl -

Displacement volume

48 µl -

Differential pressure range

0 bar (73 psi), (40 bar (580 psi) *) -

Maximum inlet pressure

80 bar (1160 psi) (inlet pressure + differential pressure) -

Ambient temperature range

0 ... +40 (+32 ... +104 °F) °C -

Liquid temperature range

-5 ... +60 °C (+23 ... +140 °F), -20 ... +120 °C * (-290 ... +248 °F *) -

Viscosity range

0.3 - 100 mPas -

Precision CV

< 1 % (Coefficient of variation CV) -

Ex-certification

CE Ex II 2G IIC c T4 X -

Place of installation

Ex-area zone 1, 2 -

Fluid connection

1/8" NPT internal thread, lateral -

Wetted parts

Pump case alloy C22 (DIN 2.4602), optional: stainless steel 316L; seals FFPM (Kalrez® Spectrum™ 6375), optional: FPM, EPDM; shaft/bearing sintered silicon carbide (SSiC); bearing and wetted functional parts Al2O3 ceramics; rotors partially stabilized ZrO2, optional: tungsten carbide Ni-based -

Motor

BLDC motor with integrated motion controller, 24 V DC, 2 A, 53 W, analog hall sensors (3000 pulses / revolution)

-

Velocity range

1 - 4,000 rpm -

Cable length

10 m -

Weight

approx. 4,900 g -

Remarks

* with optional heat insulation module; Customized solutions on request. Notice

Even if single parameters are within the indicated performance range of technical data, certain parameter combinations may not be achievable. Single parameters may exceed their indicated performance range under adequate circumstances. For detailed evaluation please contact HNP Mikrosysteme. Actual performance may vary. Specifications are subject to change without notice.

This document is subject to change without notice.

Show more Downloads

Back to list