For industrial production and process technology

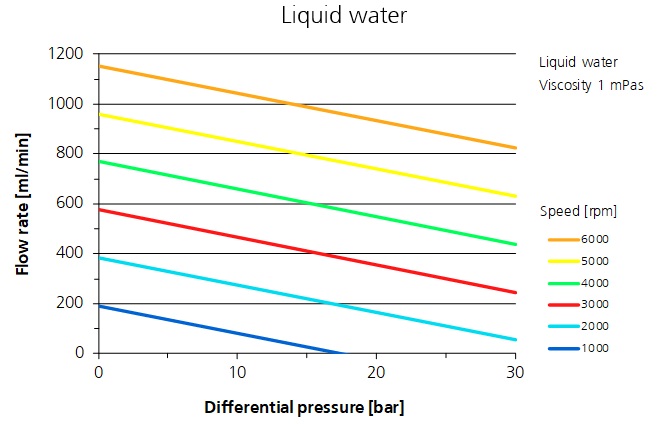

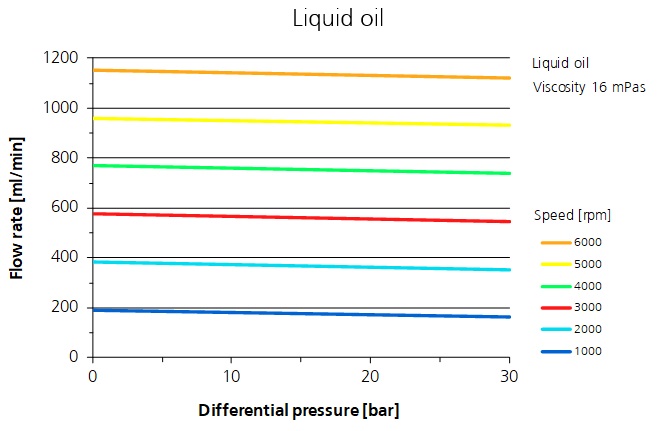

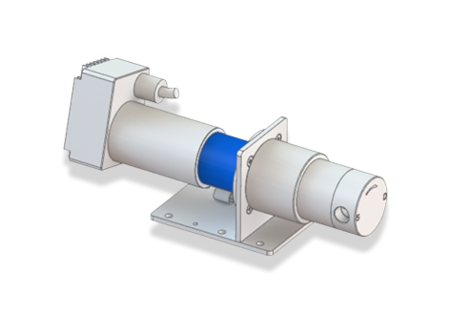

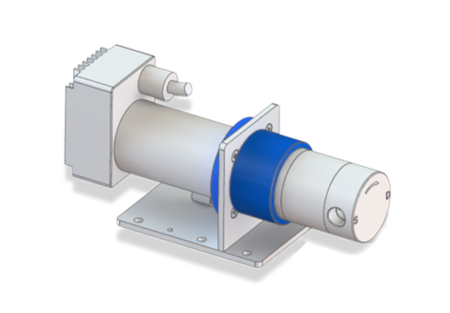

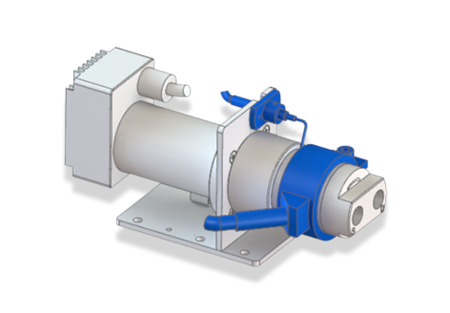

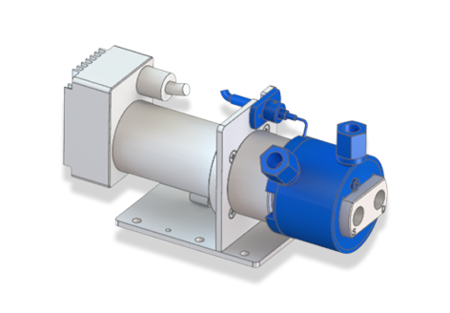

The micro annular gear pump mzr-11508X1 is equipped with tungsten carbide rotors and bear-ings. Hard construction material and precision manufacturing techniques guarantee excellent dosage precision, high service life and wear resistance for low volume dosage of non-lubricating liquids. Driven by a high-power DC-motor the pump has a compact design and covers the flow range from 0.19 ml/min to 1152 ml/min. The mzr-11508X1 is suitable for continuous delivery and discrete dosage of high viscosity liquids. It achieves high differential pressures and provides a low pulsation flow. Its robustness and the available accessories make it suitable for challenging applications.

Advantages

- High dosage precision

precision CV < 1% at low volumes - Long service life

wear-resistant tungsten carbide - Broad viscosity range

methanol, water, solvents, adhesives, grease, gel - Dynamic precision motor

brushless DC-motor with encoder - Compact dimensions

length 265 mm - High differential pressures

achievable even for low viscosity liquids - Low pulsation delivery, low shear stress

rotary micro annular gear technology

Applications

- Chemical processing

- Industrial and plant engineering

- Packaging

- Medical and pharmaceutical industry

- Mini plant technology

- Spraying

- Dispensing of adhesives

- Ink and paint dosage

- Vacuum applications

Flow charts

Technical data

Show moreDownloads

-

-

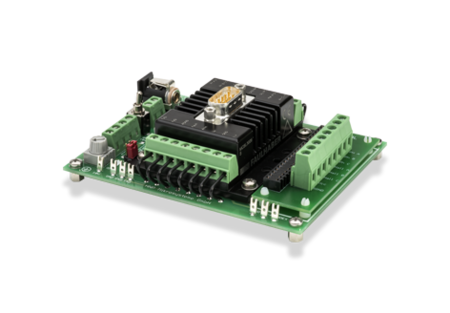

Software

-

-