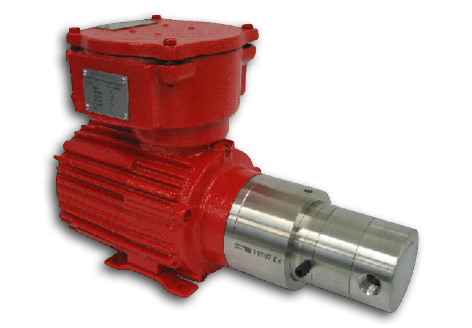

Ex-pump for application in chemical and process technology

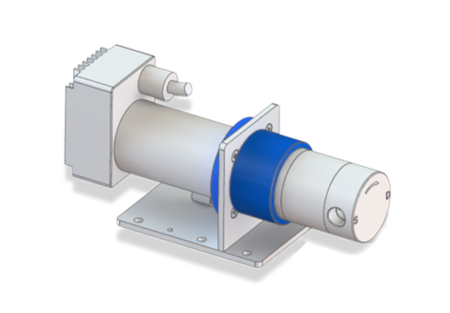

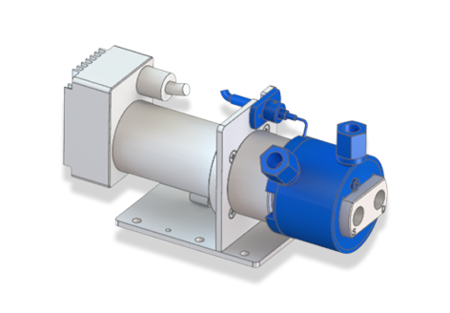

The micro annular gear pump mzr-11507 Ex is equipped with tungsten carbide rotors and bearings. Hard construction material and precision manufacturing techniques guarantee excellent dosage precision, high service life and wear resistance for low volume dosage of non-lubricating liquids. Driven by a explosion-proof three-phase AC-motor the pump has a compact design and covers the flow range from 58 ml/min to 1152 ml/min. The mzr-11507 Ex is suitable for continuous delivery of low and high viscosity liquids. It achieves high differential pressures and provides a low pulsation flow. Its robustness and the available accessories make it suitable for challenging applications in chemical and process technology.

Advantages

- Ex-certification ATEX

conform with EU Directive 94/9/EG - High dosage precision

precision CV < 1 % at low volumes - Long service life

wear-resistant tungsten carbide - Broad viscosity range

water, solvents, adhesives, grease, gel - Compact dimensions

length 358 mm - High differential pressures

achievable also for low viscosity liquids - Low pulsation delivery, low shear stress

rotary micro annular gear technology

Technical data

-

Flow rate

58 – 1,152 (29 - 576 *) ml/min -

Smallest dosage volume

100 µl -

Displacement volume

192 µl -

Differential pressure range

0 – 80 bar (1,160 psi) -

Maximum inlet pressure

10 bar (145 psi) -

Ambient temperature range

-20 ... +40 °C (-4 ... +104 °F), -55 ... +60 °C * (-67 ... +140 °F) * °C -

Liquid temperature range

-5 ... +40 °C (+23 ... 104 °F), -20 ... +120 °C * (-4 ... +248 °F) * -

Viscosity range

0.3 - 5,000 (10,000 *) mPas -

Ex-certification

CE Ex II 2G Ex h IIC T4 Gb -

Place of installation

Ex-area zone 1, 2 -

Precision CV

< 1 % (Coefficient of variation CV) -

Velocity range

300 - 6,000 (150-3,000 *) rpm -

Fluid connection

3/8" NPT internal thread, lateral optional 3/8" NPT internal thread, frontal -

Wetted parts

stainless steel 316L (1.4435), tungsten carbide Ni-based; shaft seal: graphite-reinforced PTFE, alloy C276 (2.4819); static seals: FPM, optional: EPDM, FFPM -

Motor

three-phase AC motor, IEC-Size 063, 2 poles, IP 55, rated voltage 240/400 V, frequency 50 Hz, 250 W -

Temperature protection

PTC-resistor, 6 pieces -

Dimensions (L x W x H)

358 x 120 x 224 mm -

Weight

approx. 22,000 g -

Remarks

* with optional modules or alternative motors, Customized solutions on request. Notice

Even if single parameters are within the indicated performance range of technical data, certain parameter combinations may not be achievable. Single parameters may exceed their indicated performance range under adequate circumstances. For detailed evaluation please contact HNP Mikrosysteme. Actual performance may vary. Specifications are subject to change without notice.

This document is subject to change without notice.

Show more Downloads

Back to list