For industrial production and process technology

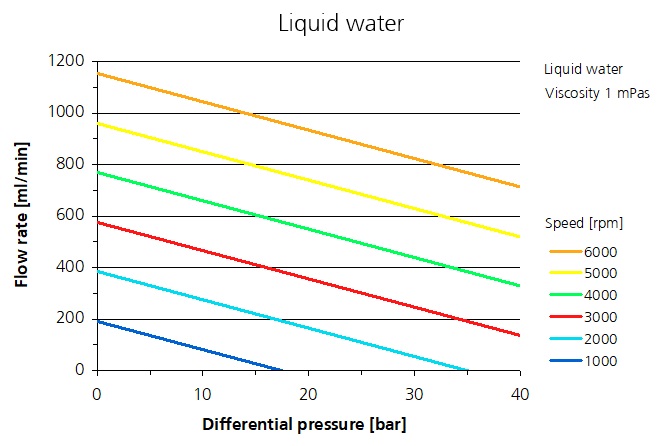

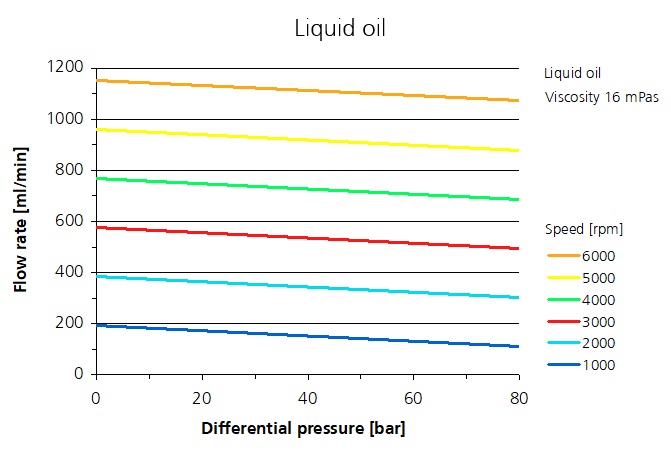

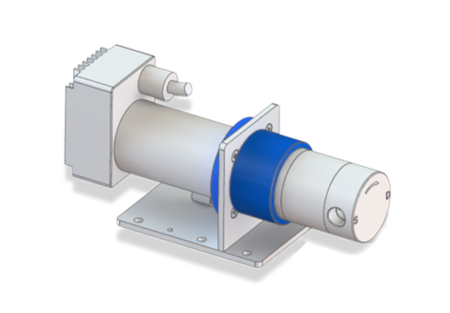

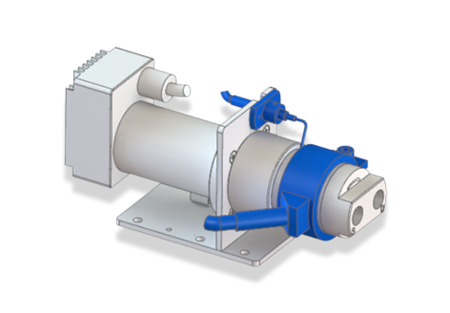

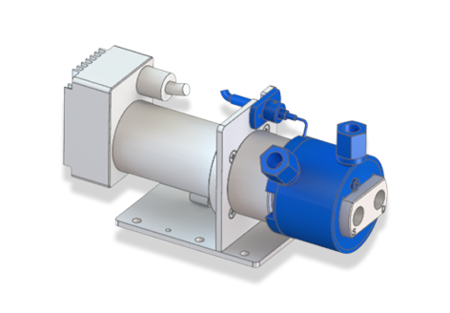

The micro annular gear pump mzr-11507 is equipped with tungsten carbide rotors and bearings. Hard construction material and precision manufacturing techniques guarantee excellent dosage precision, high service life and wear resistance for low volume dosage of non-lubricating liquids. Driven by a high-power three-phase AC-motor the pump has a compact design and covers the flow range from 29 ml/min to 1152 ml/min. The mzr-11507 is suitable for continuous delivery and discrete dosage of low and high viscosity liquids. It achieves high differential pressures and provides a low pulsation flow. Its robustness and the available accessories make it suitable for challenging applications.

Advantages

- High dosage precision

precision CV < 1% at low volumes - Long service life

wear-resistant tungsten carbide - Broad viscosity range

methanol, water, solvents, adhesives, grease, gel - High-power motor

AC-motor for use with external frequency inverter - Compact dimensions

length 303 mm - High differential pressures

achievable even for low viscosity liquids - Low pulsation delivery, low shear stress

rotary micro annular gear technology

Applications

- Chemical processing

- Industrial and plant engineering

- Packaging

- Medical and pharmaceutical industry

- Mini plant technology

- Spraying

- Dispensing of adhesives

- Ink and paint dosage

- Vacuum applications

Flow charts

Technical data

Show moreDownloads

-

-