Compact hermetic pump for continuous dosage

The micro annular gear pump mzr-4661 is suitable for handling crystallizing, oxygen or moisture sensitive liquids, because the pump has no shaft seal. This functionality is made possible thanks to a liquid-separating cup surrounding the magnetic drive. The compact dimension of this magnetic hermetic pump is achieved by a completely new product design and optimal matching with an integrated speed controller. With a diameter of 22 mm and 69 mm in length, the pump weighs 115 g. The pump handles flow rates from 4.8 to 72 ml/min with a high precision and low pulsation. The pump is suitable for applications where an avoidance of leakage and a long service life as well as low energy consumption are important requirements. The pump is supplied with a terminal box for speed control and LED status indicator.

Advantages

- Hermetic pump design

pump without shaft seal - Magnetic drive

inner magnet system driven by rotating magnetic field - Integrated controller

supply voltage 24 V DC, speed control by analog input 0-10 V - Compact dimensions

diameter 22 mm, length 69 mm - Long service life

wear-resistant, ultra-hard materials

Applications

- Fuel cells

- Dosing of AdBlue

- Mobile analytics

- Biotechnology

- Marine technology

- Metering of liquefied gases

- Aerospace industry

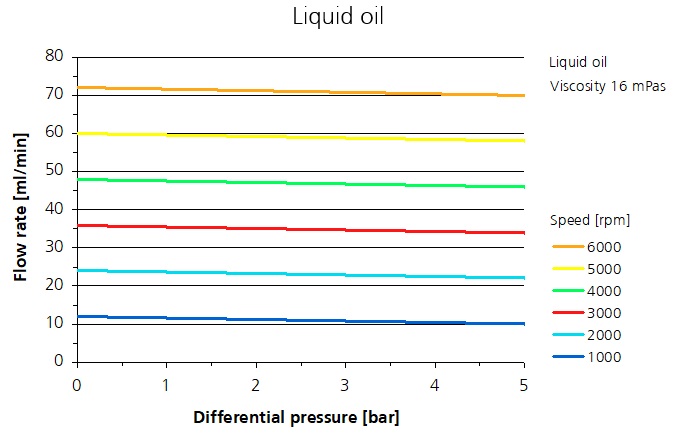

Flow charts

Technical data

-

Flow rate

4.8 - 72 ml/min -

Displacement volume

12 µl -

Maximum system pressure

6 bar (87 psi) (60 bar (870 psi)*) (inlet pressure + differential pressure) -

Differential pressure range

0 - 5 bar (73 psi) -

Ambient temperature range

-20 ... +65 (-4 ... +149 °F) °C -

Liquid temperature range

-15 ... +60 °C (+5 ... +140 °F) -

Viscosity range

0.3 - 50 mPas -

Velocity range

400 - 6,000 rpm -

Fluid connection

slip fittings with outside diameter 2 mm optional: manifold assembly M2.1 -

Wetted parts

stainless steel 316L, 318LN, tungsten carbide Ni-based, ceramics, epoxy resin,

optional: alloy C22, tungsten carbide Ni-based, ceramics, epoxy resin;

titanium, tungsten carbide Ni-based, ceramics, epoxy resin;

stainless steel 316L, 318LN, ceramics, epoxy resin;

alloy C22, ceramics, epoxy resin;

titanium, ceramics, epoxy resin;

seals: FPM, optional: EPDM, FFPM -

Motor

canned BLDC-motor, 24 V DC, 8.9 W -

Controller

integrated speed controller -

Interface

0–10 V -

Electrical connection

6-pole connector, Micro-Fit -

Dimensions (L x W x H)

Ø 22 mm, length 69 mm -

Weight

approx. 115 g (manifold assembly approx. 145 g) -

Remarks

*Customized solution on request. Notice

Even if single parameters are within the indicated performance range of technical data, certain parameter combinations may not be achievable. Single parameters may exceed their indicated performance range under adequate circumstances. For detailed evaluation please contact HNP Mikrosysteme. Actual performance may vary. Specifications are subject to change without notice.

This document is subject to change without notice.

Show more Downloads