MoDoS - Dosing tasks from lab to fab

The Modular Dosing System MoDoS® is a tailor-made pump system for continuous production process in fine chemical and pharmaceutical production.

MoDoS is synonym for a design concept and a component kit, forming the base for the development of a customized pump module. We provide detailed advice on the selection and integration of components.

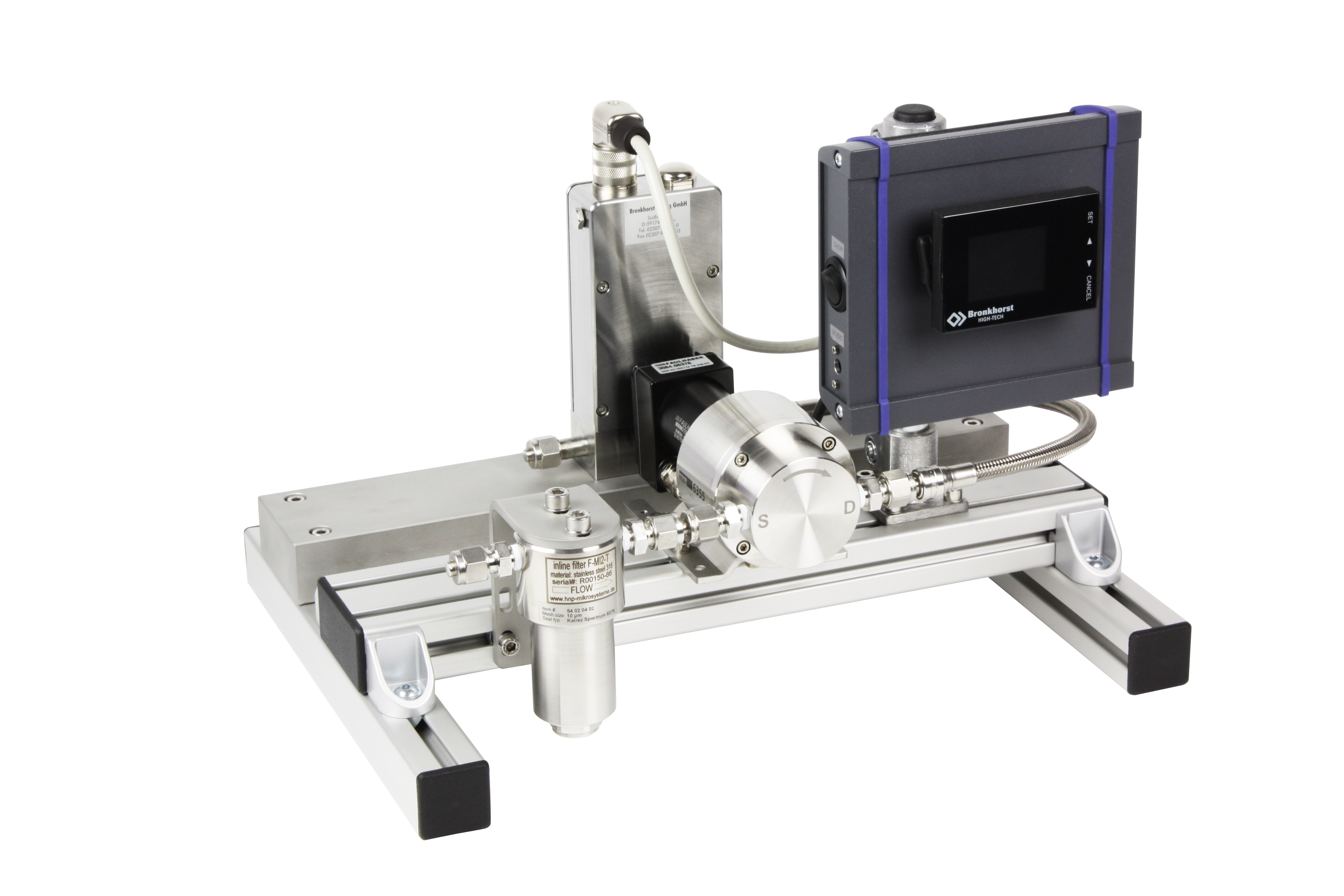

You will receive a tested and ready-to-use dosing system in a stable frame. The selection of sensors for flow, pressure or temperature is carried out on the process parameters. We use flow sensors from different manufacturers, based on various thermal principles or on the Coriolis principle.

MoDoS is a complete solution for process-safe pumping in the low-volume range, suitable for vaccines, APIs, acids, alkalis, catalysts, ammonia and much more.

Advantages

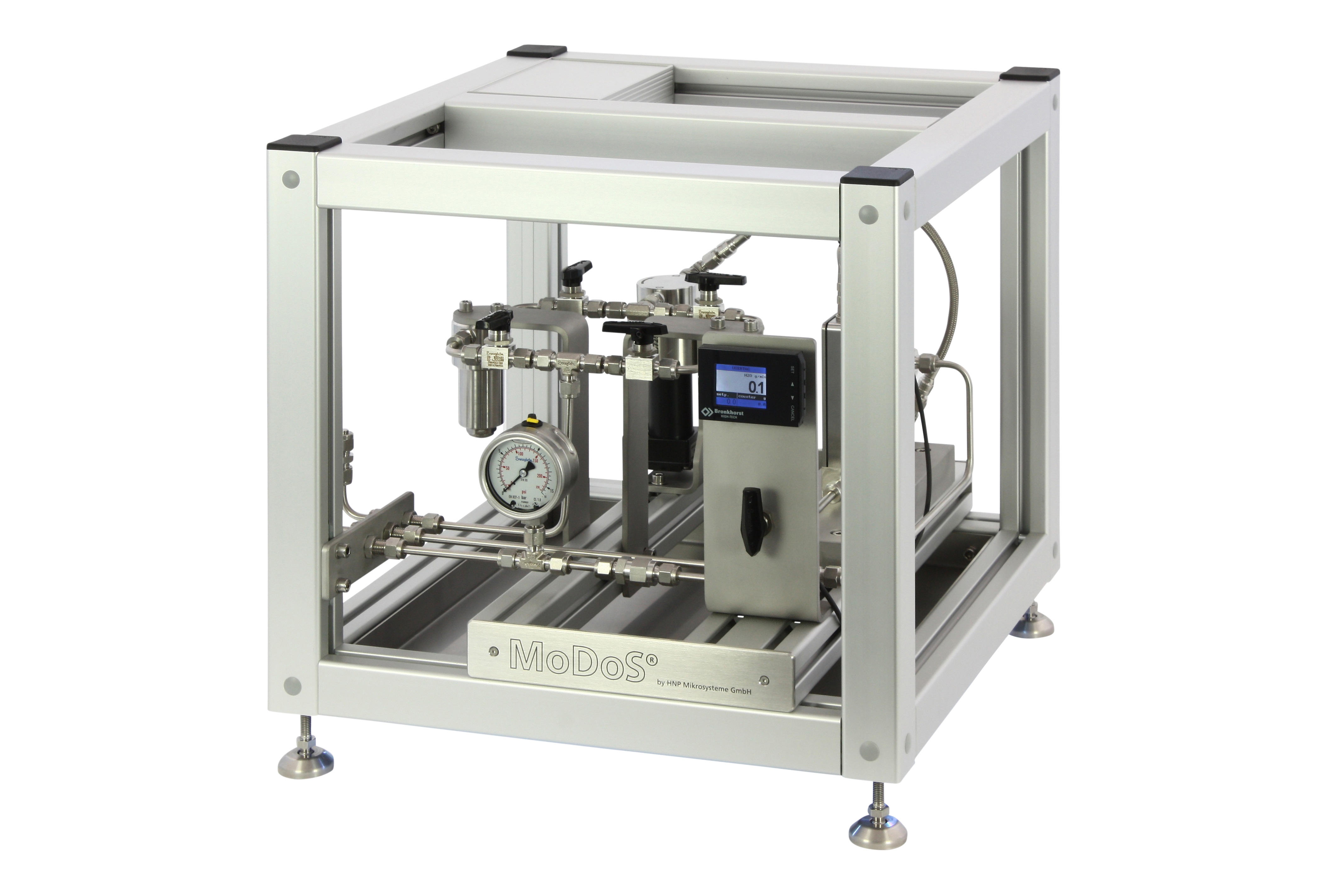

- Ready-to-use unit

fully equipped and assembled system in a rigid framework - Modular system of components

individually equipped with micro annular gear pump, filters, sensors (e.g. flow, pressure, temperature) valves, fluid connections - Chemical resistant materials

material combinations from stainless steel / hard metal to alloy C22 / ceramics, optional titanium - High process stability

mass or volume flow controlled micro annular gear pumps - Standard fluidic interfaces

screw-in fittings or aseptic µ-Clamp - Local controller

integrated controller allows stand-alone mode as well as inte-gration into external process control systems - Open design

easy access and exchange of all components

Applications

- Micro process technology

- Flow chemistry

- Fine chemistry

- Pharmaceutical production

- Miniplant technology

- Dosing and filling

Typical Liquids

- Acids and bases

- Organometallic compounds, butyl lithium

- Catalysts

- Ammonia, pure or in solution

- Pharmaceutical ingredients and vaccines

- Solutions of radioactive isotopes

- Organic reagents

Components

- Micro annular gear pump

- Sensors for flow, pressure, temperature

- Display Control

- Filter

- Valves, shut-off elements

- Screw-in fittings, adapters

- Hoses, pipes

- Frames

Versions and examples

MoDoS Pro

mzr-pump, redundant filters, flow meter, control unit box; L x W x H: 57 x 57 x 57 cm

Download images

Technical data

Show moreDownloads

-

Configurations

-

-

-

-